Last Updated on 2 years by meredith.wang

A finished LED product entails a series of complex manufacturing steps and processes. During these processes, variation occur and the actual performance may vary between LEDs within the same product family. To help you end customers manage the variability, LED manufacturers have developed a technique called LED binning to classify LEDs.

How LED Binning Range Matters for Color Consistency?

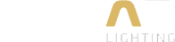

To sort out the LEDs by color temperature, they are individually measured and sorted into prescribed bin ranges. The wider a bin range is, the more variations are to be expected and vice versa. If a manufacturer goes with a wide bin range they will generally pay less for their LEDs, usually resulting in a cheaper final product. As appealing as the lower price sounds, it might have unwanted implications on the quality and consistency of the product.

The following chart shows you why even for the same color temperature, visual experience may vary if chromaticity coordinates X, Y locate far apart. The closer to the Planckian locus in chromaticity diagram, the more natural the light feels.

The diagram below demonstrates how 3500k light fixtures can exhibit slight color difference.

What is MacAdam Ellipse?

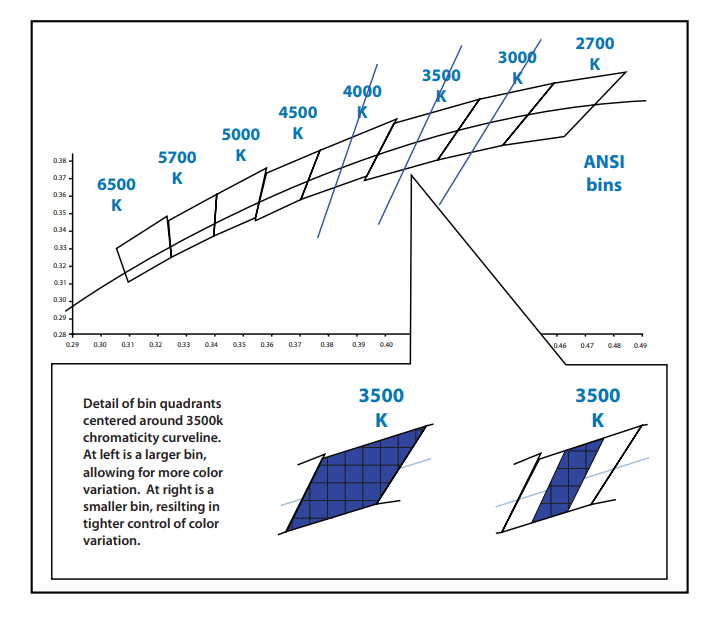

Manufacturers sort their LEDs according to the ANSI (American National Standards Institute) standard in order to ensure they are the same color temperature. ANSI defines chromatic aberrations using the MacAdam ellipse, an area in a chromaticity diagram which contains all colors that are indiscernible to the naked eyes, from the color at the center of the ellipse.

| SDCM | Visibility |

|---|---|

| 1 SDCM | Almost impossible to see a difference |

| 2 SDCM | Differences seen through measuring instruments |

| 3 SDCM | Less color differences visible |

| 4 SDCM | Visible color differences |

| 5 SDCM | Clear color differences |

What is LED Binning?

In the lighting industry, LED binning is commonly known as the process of sorting LEDs according to various quality criteria such as color, voltage, and brightness. LEDs are usually divided into bins based on their performance at a specified operating condition. This approach improves the consistency of the LED performance for the end user.

Lumens and color are the most important parameters in LED variability. Binning according to lumens is relatively simple to define whereas binning LEDs according to color is more complex. To help you understand the process, we think you need to know about chromaticity diagrams.

Why Color Consistency is Especially Important for Linear LED Lights?

When you have an LED bulb with a cluster of LEDs, one LED that’s a little shade off of color will average together. But with a linear LED lighting product, it is critical that every LED be SPOT ON. When you’re lighting up a cove with a linear light, like against the white ceiling, an LED that doesn’t have perfect color will immediately reveal itself. When you do your project, you want to know that it’s going to look perfect for years from now.

What Is “One Bin”?

“One Bin” is a custom standard that varies from manufacturers to manufacturers, referring to the method that LED chips are sorted according to one single shade of white. Many manufacturers love to pride themselves on how they make quality lighting products by only using one bins for their LEDs. But simple one bin method doesn’t guarantee color consistency all the way to the finished products, as one bin could mean a tight or loose bin range.

LED Binning for LED Chips Guarantees for Color Consistency for Final Products?

For sure, consistent LEDs according to binning pave the way for consistent final products. But the binning process alone doesn’t mean that consistent final products are in the bag. How the products eventually turn out to a large extent depends on how manufacturers manage all the variables at play during the production such as materials of different batches, workmanship, production conditions, among other things.

For instance, you can have a batch of LED chips that are kept in 2SDCM and end up with final luminaires that shift to 7SDCM if something is not done right with materials, workmanship or production runs. Therefore, it takes enormous experience and dedication to pull off consistent LED products from production runs to production runs.

How CLEAR Deals with Color Consistency?

Variation can be found in individual LEDs on a single tape and LED strips in different batches. For the color consistency of finished products, PVC or silicone type, CLEAR complies with the international standard, ANSI C78.377-2015, and keeps them within 3SDCM in which the human eye can’t detect any color shift.

As a leading manufacturer in the industry, we’re keenly aware of how color consistency can make or break a project. With that understanding in mind, we make the best use of our expertise and experience to exercise tighter control over materials and manufacturing procedures, as well as professional measurement and calibration of chromaticity coordinates of LEDs and final products. All these efforts paid off as we have successfully helped hundreds of lighting designers and installers deliver successful lighting projects in a wide array of sectors such as retail, medical and industrial sectors.