- Home

- >

- ClearTech

ClearTech™

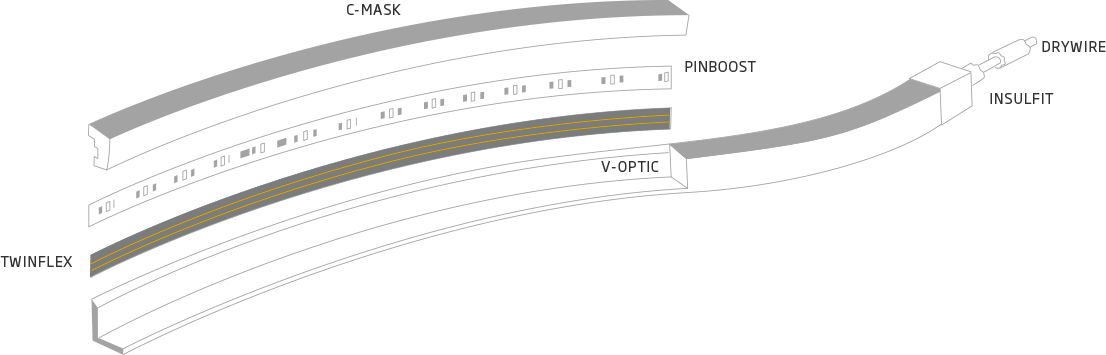

The following technologies are developed by Clear Lighting specially for LED flex linear light and collected in ClearTech™.

Hereby, we would like to pay tribute to our colleagues who have taken unremitting efforts to make significant contribution to these technology development as well as our business partners who have constantly driven us to improve over the past 20 years.

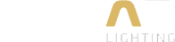

PinBoost™patent

The FPCB, used as the main current-carrying conductor in the LED flexible linear light, could not protect SMT components from wielding off and prevent light source bracket damage when bend or twist the light due to its flexibility can not withstand large external mechanical force.

The core technology of the PinBoost™ is to place reinforcement components on both sides of the SMD LED, effectively reducing damage to SMT LEDs on the FPCB due to external forces caused by incorrect bending and distortion.

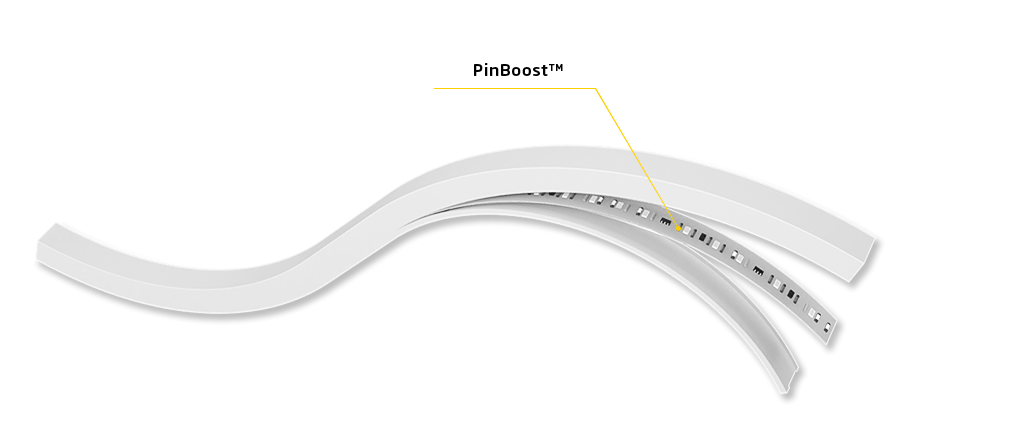

DryWire™patent

When electrical products are used outdoors or in high humidity environment for a long time, affected by the wire capillarity effect, water and moisture often slowly penetrate the inside of electrical equipment from the conducting wire, which will lead to equipment short circuit damage.

The core technology of the DryWire is to block the passage of water and moisture into the light and protect the light from water ingress through conducting wire.

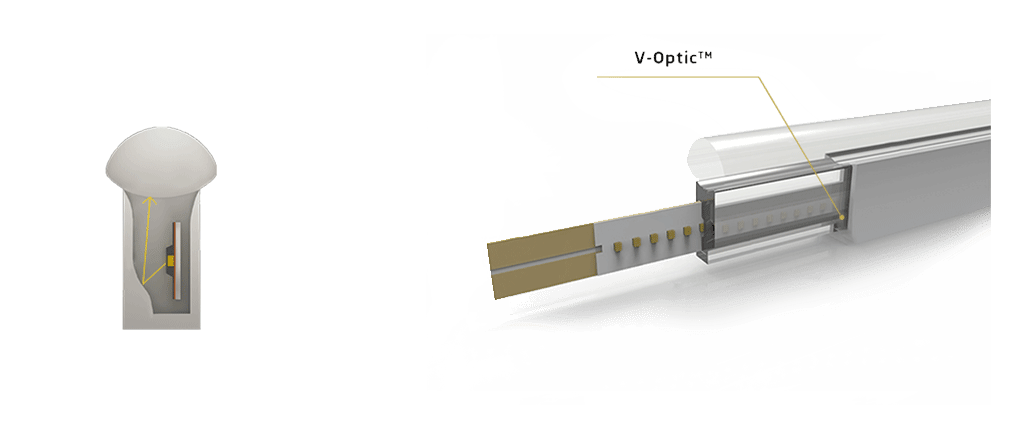

V-Optic™patent

The LED flex linear light with FPCB normally can only be bent up and down against the light surface. To achieve horizontal bending, FPCB will be placed vertically inside but with low brightness, or mounted with side emitting LEDs but the light source’s options are limited and high cost.

The core technology of the V-Optic™ is a unique internal reflection angle design and reflective material formulation, which maximizes lumen output with general SMT LEDs and controls the color temperature shift of the light.

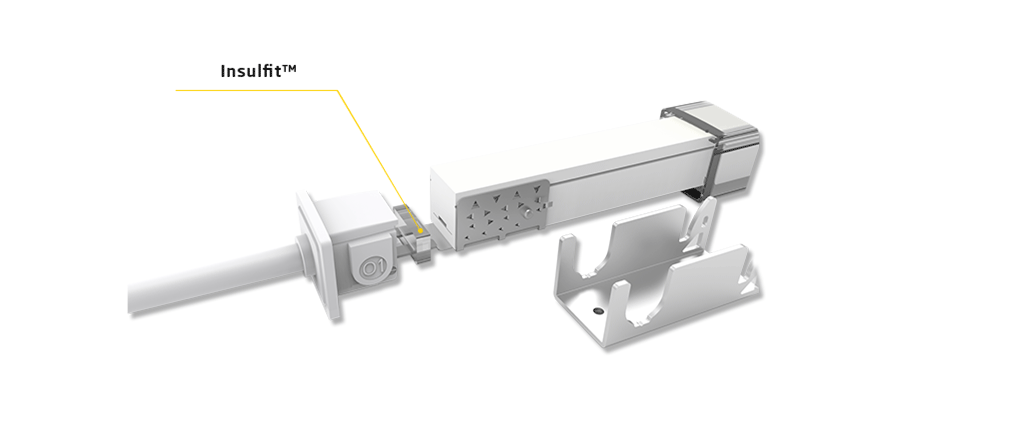

Insulfit™patent

Traditional light strip and neon light adopt stranded wire as conductor and use inserted pins as input Connector, still used by many companies. Glue and plastic heat-shrink tube enable the Connector to be waterproof, but too many failures had demonstrated this kind of Connector’s high risk of water ingress issues, especially for outdoor use.

The core technology of the Insulfit™ is to integrate mechanical design and water-repellent chemical’s advantages. By assembling the mechanical Connector to squeeze the special formula silicone gasket coated with sealing silicone grease, we can hermetically seal the

light end.

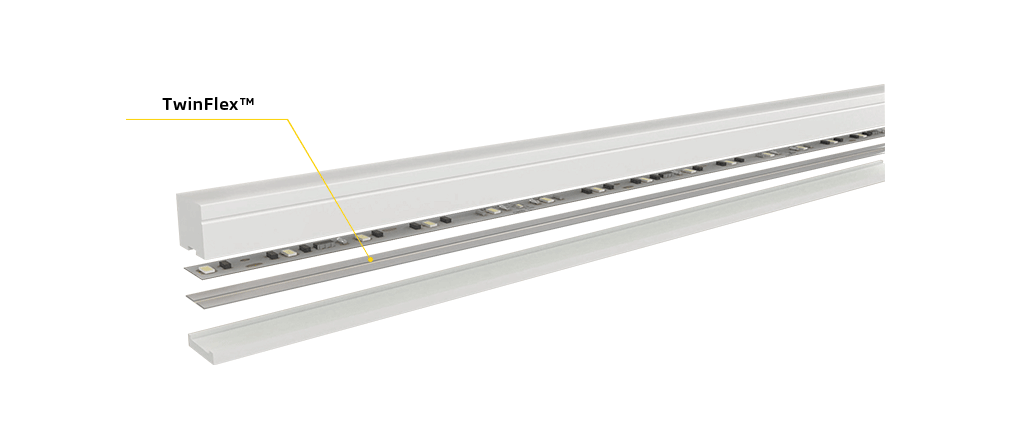

TwinFlex™patent

In recent years, FPCB has been introduced into the flexible linear light as conductor, along with SMT technology development, which improve the

production efficiency of LED flexible linear light and extend the product’s function, while also limiting the development of LED flexible linear light because of its flexibility.

The TwinFlex™ technology integrates FPCB with copper belt. This pioneering technology dramatically improve the performance of this kind of products, including reinforced mechanical strength, enhanced heat dissipation, broadened Connector pin connection, and augmented conductor with duplex circuit transmission to increase current carrying capacity and reduce voltage drop.

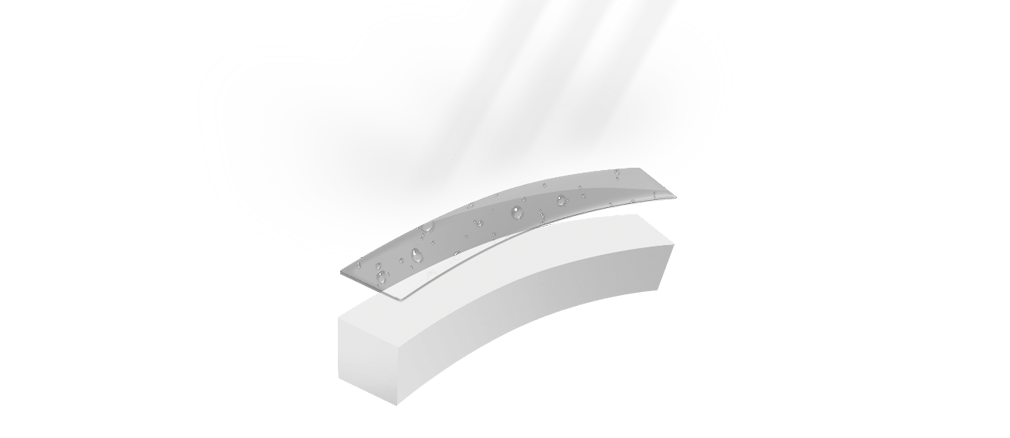

C-Mask™(PVC)

UV rays can damage the chemical structure of plastic material lighting product and dust can accumulate on the surface of the product in outdoor environment. If the surface is not cleaned regularly, the absorbed dust will affect the brightness and color of the product.

The technology of the C-Mask™ (PVC) creates a seamless bond on the top surface of PVC LED flexible linear light that is water-repellent and will protect the surface from UV, dirt, corrosion and decay, thus enabling an overall consistent illumination and prolonging light’s lifespan in outdoor applications.

C-Mask™(Silicone)

Dust can accumulate on the surface of the plastic material lighting product in outdoor environment due to weather conditions. If the surface is not cleaned regularly, the absorbed dust will affect the brightness and color of the product.

The technology of the C-Mask™(Silicone) decreases friction and static electricity of light top surface , which will protect the surface from dirt and scratch, thus improving the appearance and prolonging light’s lifespan in outdoor applications.