Last Updated on 10 months by meredith.wang

SafeGlo TM Explosion Proof LED Flex Light is world’s first IECEx and ATEX certified flexible explosion proof led lights. These Ex-proof flexible LED lights are built to provide functional lighting for compact spaces and continuous contour lighting in hazardous areas that have not imagined before. These lights can be applied to many industries and this blog will take you through some of the inspiring application ideas where you can use the explosion proof flex lights.

Onshore Oil Drilling

On-shore oil fields are facilities that are dedicated to harvesting oil from land. These facilities may or may not operate next to water. Explosion proof flex lights are Class 1 certified to withstand hazardous location where light fixtures are at a risk of explosion proof due to the buildup of gasses. These intrinsically safe flexible lights are lightweight and can run continuously. They are very easy to install and maintain. You can simply attach the light strip to the handrails in order to increase work site visibility and reduce slips and trips. Or strap it to the pipes or tower for outlining, no screws and bolts needed.

Offshore Oil Drilling

Unlike onshore oil drilling, lighting for offshore oil drilling platforms is even more demanding. Constant exposure to seawater spray and salt water-saturated air presents a higher risk of corrosion compared to inland applications.

SafegloTM explosion proof flex is constructed using silicone encapsulation and withstands salt spray tests, making it fully capable of resisting severe corrosion conditions in offshore platforms. The light insulates salt water evaporation from forming a thin salty film on the lighting surface, which may reduce light intensity. In the meanwhile, the special treatment also enables the light to expose to UV rays constantly without compromising the performance.

In addition, these luminaires are also IP67 rated and comes with stainless steel profile, allowing to endure the full force of the environmental conditions such as hail and heavy rain. The ex-protected LED light strips are highly efficient and offers a lifespan up to 50,000 hours. This really helps to eliminate maintenance costs and significantly reduces power consumption, which matters a lot given the difficulty of gaining access to an offshore rig or wind farm compared to land-based applications.

Surface Mine Conveyor Belt

A mining conveyor belt transports ore and other materials from the mining site to processing facilities or loading areas. Sufficient lighting are required along the conveyor belt so that workers can see any potential hazards or issues with the material being transported.

One of the major challenges for industrial conveyor lighting is consistent illumination, which can be tricky considering the long-run belt. The second challenge for surface mine lighting is the tough weather conditions that might entail high winds, salty and wet air and humid environments. Traditional explosion proof lights seem like a great fit as they are robust and weatherproof. However they are some glaring downsides in terms of installation. Firstly, these industrial lights are bulky and heavy, thus not easy to install. Furthermore, you need poles to install the lights, which adds to the budget. Last but not least, you have to plan the spacing of lights ahead in order to obtain even light distribution.

By contrast, SafegloTM are light and flexible, can run continuously along the conveyor belt to provide consistent slighting. They are very easy to install and can be directly attached to the structure of the conveyor system, requiring no poles, screws or bolts as well as pre-planning of spacing.

Underground Mine Conveyor

An underground mining conveyor system is the opposite of the open pit mining conveyor system mentioned above and is mainly used to mine mineral ores in the formation. It is installed below surface of the ground. Compared to surface mine, underground mine offers confined space. SafegloTM LED Flexible Light can be installed up in the ceiling using the suspension kit, or attach to the pipe/mesh on the wall upward to illuminate the belt evenly.

Unlike surface mine, underground mine is drier and more likely to build up dirt and dust. In response, SafegloTM LED Flexible Light has the perfect solution as C-Mask technology protects the light surface from buildup of dirt and dust, significantly reducing light loss decay thereof.

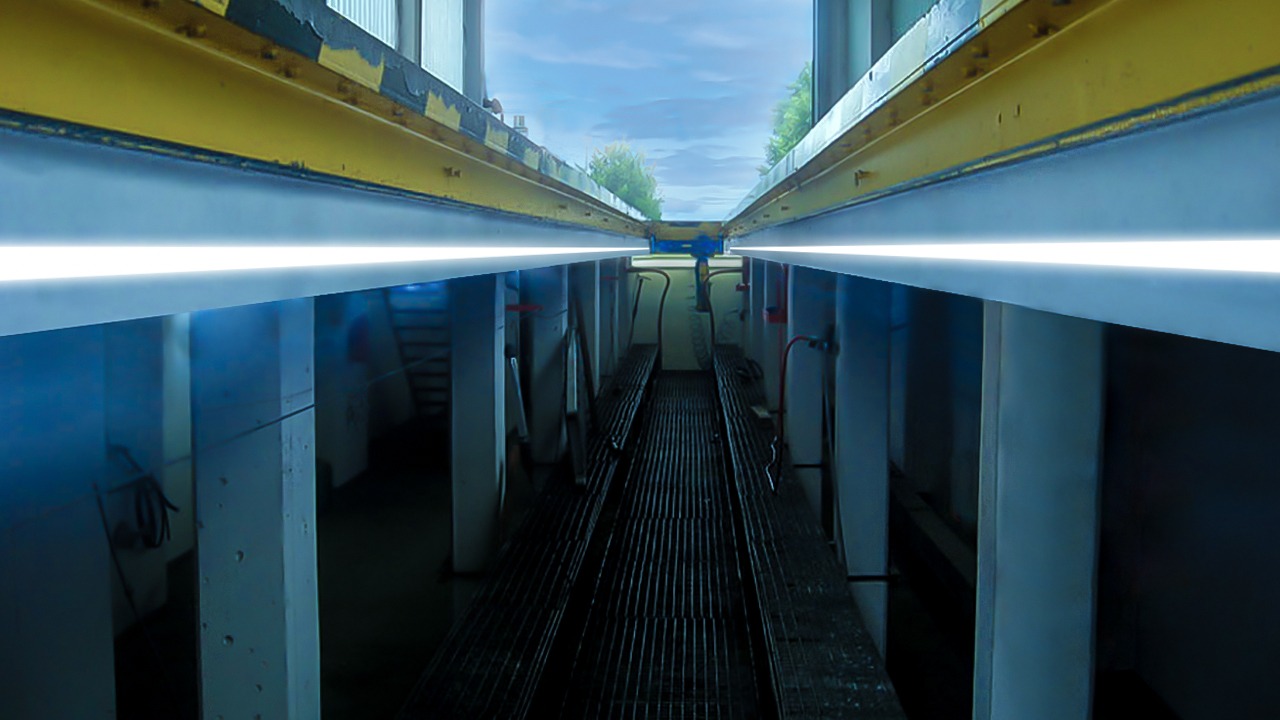

Service Pit

Flammable gas such as fuel, and diesel exist in garage pits, pit lights are normally explosion-proof lighting to avoid the explosion while allowing technicians to undertake inspection and precise maintenance in a well-lit confined place.

Traditional pit lighting fixtures are bulky, failure prone, and difficult to install. The long range pit usually need multiple lighting fixtures in order to get sufficient lighting, which adds to the budget and difficult of installation and maintenance.

SafegloTM LED Flex Light is compact and low profile, offering easy and discreet mounting options. SafegloTM can run continuously along the pit wall of either side, which not only makes it easier to install but also delivers evenly distribution of light without leaving blind spots. Explosion Proof LED Flex Series is Class 1, Division 2 hazardous locations rated for areas where exposure to fuel, oil, hydraulic fluid and other combustible materials may be present in a maintenance pit.

Gas Station

In gas stations gases and vapors could reach the upper parts of the constructions and ignite in contact with the luminaries. Differently than other lights, the ones used in gas stations must be able to disarmed themselves internally in order to avoid a secondary explosion and don’t risk users in the locations. Explosion Proof Flex Light can bring something different to the station. You can have the strip light to outline the perimeter of canopy using RGB colors to give the place a unique identity. Also, you can mount it under the pump base to highlight the fuelling pump.

Distillery & Beverage Production

Distilleries can be hazardous areas due to the flammable nature of the raw materials and the final product. These areas could vary from grain warehouses where layers of dust across surfaces build up, distillation areas where heat would reach up to 70°C in producing alcohol and the vapor give off, as well as barrel storage area where explosive ethanol vapor found in barrel storage.

Compared to traditional explosion proof led linear lights for distilleries, SafegloTM LED Flex Light are slim and has an inconspicuous appearance, which helps to fit in with the environment and thus contributes to ease of installation and the overall aesthetics of the place. Plenty of distillery usually have medium to low ceiling space where you can make the light a pendant one using a suspension kit or mount it on the beam structure as a ceiling light. Thanks to linear long runs, the cellars or distillery room will have ample lighting, leaving no dark areas. The Explosion Proof LED Flex Light Series is Zone 1/2 and Zone 21/22 hazardous area, which covers the entire distillery.